Refractory Concretes for Aluminium Industry

REYMA MATERIALES REFRACTARIOS, S.A. has a specific line of refractory concretes for the aluminum industry for applications such as holding and melting reverberatory furnaces, rotary furnaces, melting towers, injection moulding machine furnaces, dosing and filter systems, transport ladles, transfer and casting channels, etc.

As a complement to the standard concrete ranges for this and other sectors, such as insulating concretes, conventional medium-cement content concretes, thixotropic low-cement content concretes and cement-free (SOL-GEL technology) concretes, as well as patching and gunning concretes, REYMA has developed specific ranges of refractory concretes designed for occasional or permanent contact with molten aluminium, reducing the possibility of metal sticking through the addition of “anti-wetting” additives while, on the other hand, reducing the formation of corundum. These concretes are primarily supplied for application by vibrocasting with hydraulic bonding, but are also available in chemically bonded versions, both SOL-GEL and quick-setting phosphate bonding.

As a complement to the standard concrete ranges for this and other sectors, REYMA has developed specific ranges of refractory concretes designed for occasional or permanent contact with molten aluminium, reducing the possibility of metal sticking through the addition of “anti-wetting” additives.

Furthermore, REYMA offers the option of manufacturing custom-made pre-cast blocks from our various ranges of concretes and supplying them after they have been tempered in an electric furnace.

For our clients in this sector, we have produced blocks such as burner blocks or muffles, impact plates for rotary kiln, channels, sections of channels or “chutes” for transfer and casting, dosing cones and hoppers, blocks for kiln floors or rotary kiln mouths, and more.

Maintaining a constant temperature of the molten metal is an important factor when it comes to liquid aluminum transfer ladles or, for example, injection molding machine furnaces. For these and similar applications, REYMA distributes microporous boards with very high insulating capacity, which also contribute to improving the energy efficiency of the equipment.

To request additional information about our Refractory concretes for aluminium industry, you may do so through our contact channels:

- REYMA Spain: +34 944 53 15 63 comercial@reyma.com

- REYMA Mexico: +52 55 5587 2984 mexico@reyma.com

- REYMA Colombia: +57 1 23 773 73 comercial@reyma.com

COMPARTE ESTE ARTÍCULO EN TUS REDES SOCIALES

COMPARTE ESTE ARTÍCULO EN TUS REDES SOCIALES

REYMA Reotix joins UNITECR 2025

We are pleased to announce that REYMA Reotix will participate in

REYMA Reotix is taking part in FICEM 2025 Technical Congress in Peru

We are pleased to announce that REYMA Reotix will be

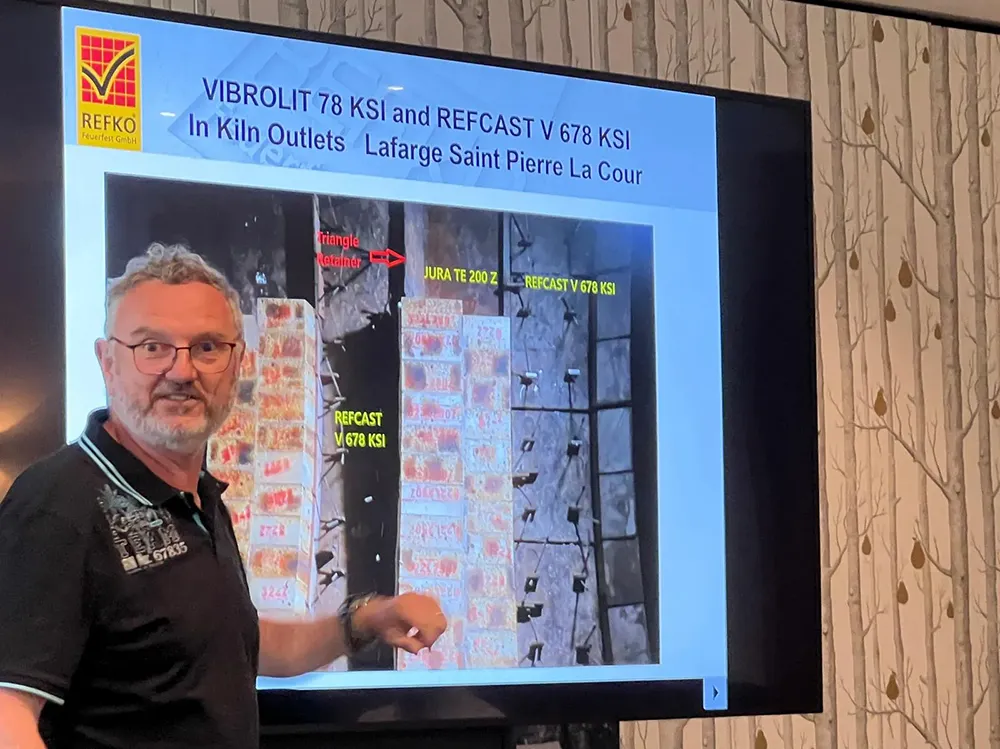

International Technical Meeting in Germany

In May, we had the privilege of participating in a